Great - water is way thinner than oil, that's a given, we all know that, right? And then. How about water? You look it up and find out that it's about 1 cSt at 20 Cº. Then you dig a bit more and discover that centistokes are mm squared over second. We work with pressures, so we get pascals, but pascal seconds?!!īut wait - there's more! So, you discover that your favorite grade 46 oil has a viscosity of 46 centistokes at 40 Cº.

#Dynamic versus kinematic viscosity manual#

Now how do you visualize square meters divided by second and then wrap your head around the fact that this somehow indicates the viscosity index of a fluid?!! Then another manual will tell you that the viscosity of a fluid is measured in Pascal seconds. Easy peasy - kilometers per hour, or meters per second, or any other measure of length divided by a measure of time. People like intuitive units because they make sense. Let me explain what I mean by "un-intuitive". And then when you look into the scientific units - you find pascal-seconds, meters squared per second, millimeters squared per second, and other very correct, but unfortunately very un-intuitive units that don't help much. You come about terms like absolute viscosity, dynamic viscosity, kinematic viscosity, poise (as /pwaz/), stokes. Done!īut if you dig" a bit deeper, and curious tech always like digging deeper - a lot of questions arise, and there aren't many "feet on the ground" answers. For example, here, in Portugal, I would choose 32 for hand pumps and equipment that works cold, 46 for "normal" hydraulics, and 68 for mobile stuff that runs at slightly higher temperatures. Practice shows that for a given range of machinery in a given region two or three oil types will cover all the bases. You'll be OK and your oil viscosity choices (or recommendations) will be sound. Practically speaking - you don't need to know more, really. The oil viscosity choice, therefore, will depend on a) the temperatures the piece of equipment will be facing during its operation cycles and b) the viscosity recommendations for the components used in the system, with 25 being the universal "bullseye" in 99.9% of cases. The high-temperature stuff "thins out" to a lesser degree. Oil gets "thinner" as the temperature rises, and there are "normal" oils and "high-temperature" oils. The numbers correspond to "centistokes" (whatever this means) at 40 Cº. You get to choose from a set of standard universally accepted viscosity grades like 32, 46, 68, etc., where a bigger number means "thicker" oil.

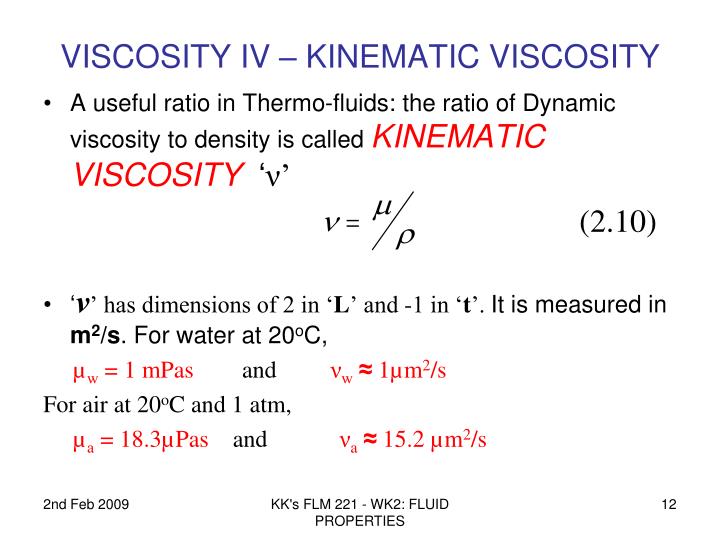

It is very important - choose it wrong and your hydraulic goes kaboom. Let us consider for a moment the simple stuff every tech knows about the viscosity of hydraulic oil: I bet all of my readers understand what the word viscosity means and know by heart the viscosity ranges of the hydraulic oil their equipment operates with, and in this regard, I won't be telling anything new, but I want to dive a bit deeper into this topic, and I if you finish this post - you'll never look at the term "viscosity" the same way as before, and will never be intimated or confused by phrases like mm squared per second, pascal-seconds, and even momentum diffusivity. Therefore, the density of fluid is 0.445 kg per cubic m.Today I will be talking about the viscosity of hydraulic oil. Formula for Kinematic ViscosityĪs we know that it is the ratio of dynamic viscosity to fluid mass density. Kinematic viscosity can be computed by dividing the absolute viscosity of a fluid with the fluid mass density. This is the ratio of the dynamic viscosity to its density, i.e. Therefore, Kinematic viscosity is the measurement of the inherent resistance of a fluid to flow when no external force is imparted except gravity.

The units of kinematic viscosity are established on time and area of fluid. It is from time to time also known as momentum diffusivity. Whereas Kinematic viscosity is the sort of viscosity that is computed by calculating the ratio of the fluid mass density to the dynamic fluid, viscosity or absolute fluid viscosity. The shearing stress between the layers of a no turbulent fluid which is moving in straight parallel lines may be defined for a Newtonian fluid. It is at a unit velocity while maintaining a unit distance apart in the fluid. dynamic viscosity coefficient is a measure of internal resistance. There are two related measures of fluid viscosity: Dynamic and Kinematic.Ībsolute viscosity i.e. Viscosity is a concept where fluid shows struggle against a flowing, which is being distorted due to extensional stress forces or shear stress. 3 Solved Examples for Kinematic Viscosity Formula Definition of Kinematic Viscosity

0 kommentar(er)

0 kommentar(er)